Our 81-acre shipyard was purposely developed to be able to take some of the world’s largest vessels and offers two of the largest drydocks in Europe.

Situated in the Port of Belfast, Northern Ireland, Harland & Wolff (Belfast) is now the beating heart of Navantia UK’s Fleet Solid Support (FSS) shipbuilding programme

Under Navantia UK’s ownership, a major modernisation programme of this historic site is underway, set to turn Belfast into one of the most advanced shipbuilding facilities in the UK.

This investment, significantly increased beyond the original FSS plans, includes infrastructure upgrades, cutting-edge manufacturing systems, and state-of-the-art automation – all designed to boost productivity, sustainability, and quality.

Our dockyard

Yard Access

Sea access to the Building and Repair Docks via Victoria Channel.

Dock size: 335m x 50.29m – Draft: 12.3m depth of water over sill at MHWS

- 6 miles to end of Victoria Channel

- Victoria Channel dimensions

- Water depth: Maintained depth of minimum 9.1m (relative to harbour datum)

- Width: 152.4m

- Height: There are no lock, bridges or other height restrictions to open

- Water: Tidal range: 3.5m

Security

- 24/7 site security

- ISPS Approved

George Best International Airport

Belfast Dock

Dock size: 335m x 50.29m – Draft: 12.3m depth of water over sill at MHWS

Cranes:

- Two 40t @ 24.3m Henson Cranes

- One 80t @ 38m Henson Crane

Further details:

- 1500m3 slops reception

- Licensed for open grit blasting

- Fully self-sufficient site with own offices amenities and workshops

Painting and Blasting cells

- Over 2,500m2 environmentally controlled painting and blasting cells adjacent to the Main Dock.

- 2 semi permanent blast and paint halls located at the head of the main dock. Can be single hall of length 70m or split into two halls of 35m and 35m accessed via removable rub roofs by gantry crane.

- 2 permanent blast and paint halls located adjacent to the Main Dock.

Fabrication & block facility

Fabrication Shops

- Over 30,000m2 covered fabrication halls

Musgrave Blocking Shop

- Overall area: 8,976m2

- Doors: electrically operated sliding panels 40m w x 18m h, sliding panel 12m w x 12m h

Musgrave Fabrication Shop

Overall area: 8,774m

Doors: 1 off 18.8m w x 11.5m h

3 off 12m w x 8m h

Key machinery:

- 200t growing line

- 6 x ESAB Sub-Arc Welding Tractors

- 2 x 7.6m x 4.3m Oerlikon C&B 4 wire manipulators

Plate Forming Shop

Overall area: 5,096m2

Key machinery:

- Messer Griesheim 2 Axis CNC cutting machine (8.53m x 35m)

- Hypertherm Plasma HPR260

- DAVI MCB 3060 drop end 4 roll track bending machine

- Guided crosshead gap press (ring frame press) 700te, forming length 2.75m (usable 2.5m)

- Gap Press 100te, forming length 2.75m core

- Statosec burner

- Multisec burner

Structural steel 100-250t per week capacity Miscellaneous steel 30-75t per week capacity

Main Dock

Dock size: 556m x 93m – Draft: 8.41m depth of water over sill at MHWS

The dock can be divided into sections by the Intermediate gate. This allows the next ship on the programme to be commenced at the head of the dock without interference when the main part of the dock is flooded to release the preceding completed hull. The intermediate gate is assembled from six main sections which are bolted to the dock floor and can be erected in four different positions including one at the entrance where it can be used to replace the main gate.

Cranes:

- Two ‘Goliath’ type gantry cranes

- Span: 140m

- Lifting height: 70m and 80m

- Safe working load: 840t and 900t

- Two 60t @ 25m Henson

- One 9t @ 40m Stothert & Pitt

Further details:

- Intermediate dock gate which can be placed at predetermined locations along the length of dock allowing a part wet, part dry arrangement.

- Over 300,000m2 of hard standing ground

- No tidal restrictions for Port entry

- Support of ship repair facility on site

Samson

Samson is the larger of our twin gantry cranes and was completed in 1974 and stands 106 metres (348ft) tall.

Goliath

Goliath was completed in 1969 and stands 96 metres (315 ft) tall – the smaller of the two cranes sits slightly further inland closer to Belfast City.

Harland & Wolff: A Legacy Forged in Steel and Sea

For over a century and a half, Harland & Wolff has stood as a symbol of engineering excellence and industrial prowess, rising from the docks of Belfast to global recognition.

Founded in 1861 by Edward James Harland and Gustav Wilhelm Wolff, the company began its journey as Edward Harland and Company before becoming Harland & Wolff in 1862 when Wolff became a partner. From its modest beginnings on a 1.5-acre site with just 100 employees, Harland & Wolff grew exponentially, transforming Queen’s Island into an 80-acre powerhouse of shipbuilding innovation and employing over 10,000 men by the turn of the century.

Harland & Wolff quickly earned a reputation for innovation, pioneering the replacement of traditional wooden upper decks with iron and adopting a flatter hull design that increased ship capacity – engineering decisions that set new standards for the industry. Early partnerships, such as the one with the Bibby Line, propelled the company into prominence, making Belfast synonymous with world-class shipbuilding by the late 19th century.

The Golden Age of Ocean Liners

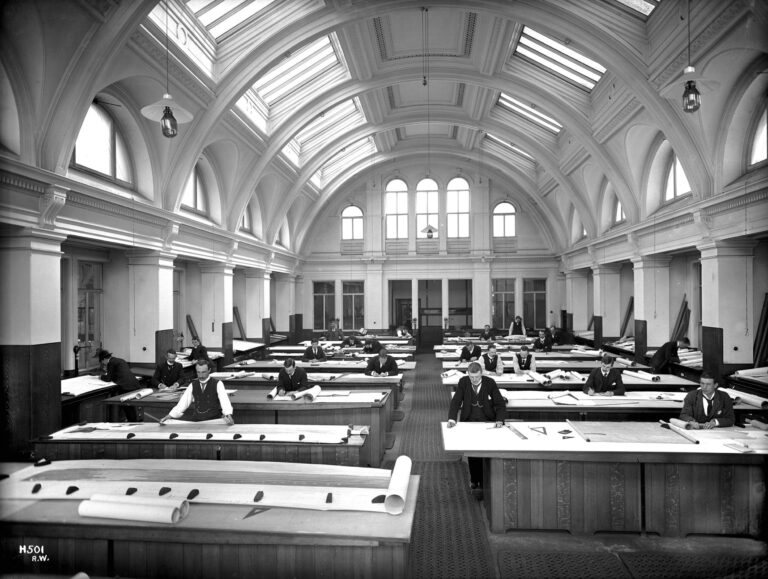

By the early 20th century, Harland & Wolff had become a leader in the construction of grand transatlantic passenger liners. The defining vessels of this era were the legendary “Olympic-class” trio built for the White Star Line: RMS Olympic, RMS Titanic, and HMHS Britannic. Launched in 1910, RMS Olympic was the largest vessel afloat at the time, a marvel of luxury and engineering.

The following year, RMS Titanic set sail, destined to become the most iconic ship in maritime history. Designed by Thomas Andrews, Harland & Wolff’s chief draughtsman and the nephew of the company chairman, Titanic’s tragic sinking in 1912 remains etched in global memory. Andrews himself perished aboard the vessel.

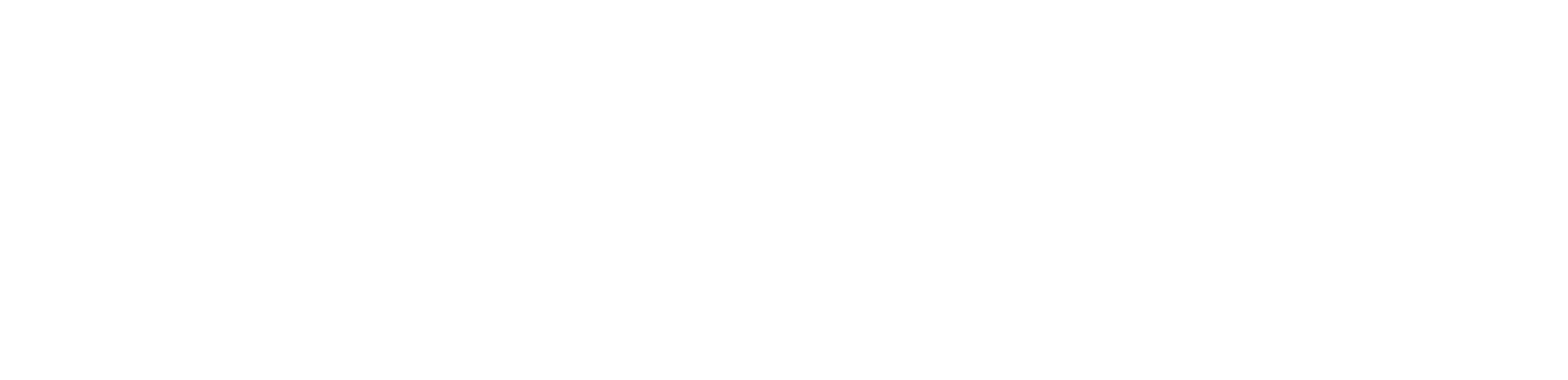

Launched in 1914, the HMHS Britannic was intended to surpass even its sister ships in grandeur. However, its fate was sealed during World War I, when it sank while serving as a hospital ship. Today, the Harland & Wolff Drawing Offices, where these iconic liners were conceived, stand as enduring landmarks.

RMS Titanic ready for launch, 1911

War Efforts and Diversification

Harland & Wolff’s legacy extends beyond luxury liners. It played a crucial role during both World Wars, building warships and repairing naval vessels for the British fleet. During World War II alone, the company constructed six aircraft carriers, two cruisers – including the famed HMS Belfast – and 131 other ships, along with modifications and repairs to over 22,000 vessels. These wartime efforts solidified Harland & Wolff’s reputation as a cornerstone of the United Kingdom’s maritime defence.

In the post-war years, the company diversified, turning its expertise to tankers, cargo ships, and commercial vessels. Expansion led to acquisitions of shipyards in Glasgow, Liverpool, Southampton, and London, reflecting Harland & Wolff’s ambition to spread its engineering mastery across the British Isles.

A burner operating at night on the deck of a ship at Harland & Wolff’s Liverpool yard

(27 October 1944)

The Future

As global competition intensified, Harland & Wolff faced new challenges, leading to its acquisition in 1989 and the formation of Harland & Wolff Holdings Plc. Shipbuilding ceased in Belfast in 2003, with the last vessel, MV Anvil Point, marking the end of an era. Yet, the company never lost its spirit of innovation, pivoting towards ship repair and offshore construction.

A new chapter began in January 2025, when Harland & Wolff was acquired by Navantia UK. This strategic acquisition marks a bold step forward, blending Harland & Wolff’s storied heritage with Navantia’s modern engineering excellence. Together, they are poised to redefine the future of maritime construction, ensuring that the spirit of Queen’s Island lives on, stronger and more resilient than ever.

From its ironclad beginnings to its resurgence in the modern era, Harland & Wolff remains a beacon of industrial legacy and engineering excellence. Under Navantia UK, its story is far from over – in fact, it’s just beginning.